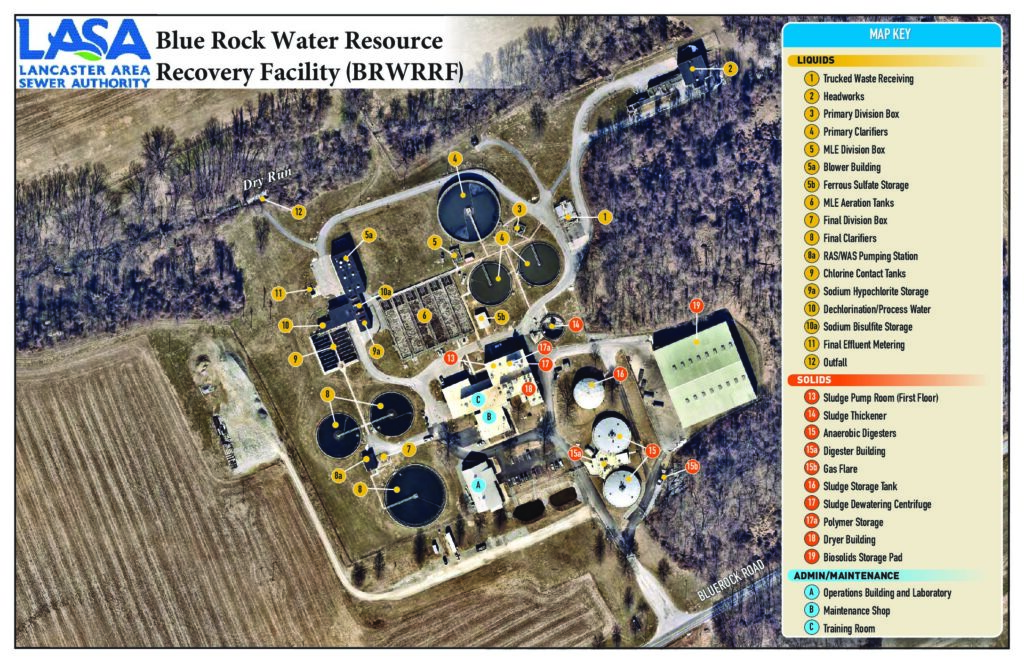

Blue Rock Water Resource Recovery Facility

Headworks

The influent wastewater flows through 2 fine screens which remove material such as rags, plastic, and wood. The screens are automatically cleaned and the material removed is deposited in a dumpster, awaiting final disposal. The wastewater then flows through vortex grit chambers where grit is removed. Grit consists of sand and small stones that can’t be removed by the fine screens. The grit removed is also deposited with the fine screenings awaiting disposal. It is important to remove these materials, because they can cause damage and excessive wear on facility equipment. The wastewater then flows into an open channel ultra-sonic flow metering flume. This measures the total flow into the facility.

The influent wastewater flows through 2 fine screens which remove material such as rags, plastic, and wood. The screens are automatically cleaned and the material removed is deposited in a dumpster, awaiting final disposal. The wastewater then flows through vortex grit chambers where grit is removed. Grit consists of sand and small stones that can’t be removed by the fine screens. The grit removed is also deposited with the fine screenings awaiting disposal. It is important to remove these materials, because they can cause damage and excessive wear on facility equipment. The wastewater then flows into an open channel ultra-sonic flow metering flume. This measures the total flow into the facility.

Primary Clarifiers

There are 3 primary tanks; 2 are 90′ in diameter and one that is 140′ diameter. The primary clarifiers are designed to remove material that easily settles and floats. Materials that are removed from these tanks are treated and disposed.

There are 3 primary tanks; 2 are 90′ in diameter and one that is 140′ diameter. The primary clarifiers are designed to remove material that easily settles and floats. Materials that are removed from these tanks are treated and disposed.

Secondary Treatment

LASA utilizes a process known as the Modified Ludzack-Ettinger (MLE) Activated Sludge Process. The MLE process is used to achieve Biological Nutrient Removal (BNR). The MLE process AO-System-from-Roofachieves BNR through nitrification/denitrification. The system has two sets of parallel tanks or trains. Each train consists of 6 sections in series. A mixture of primary effluent and return activated sludge, commonly known as the biomass, flows first into 3 smaller anaerobic selector zones that are mechanically mixed. This is where denitrification occurs. Flow then passes into the aerated zones where diffused air mixes the biomass and provides it with the required oxygen. This is where nitrification occurs. The biomass also converts suspended, dissolved and colloidal material into settleable material, where it can be removed by settling in the next stage of the process.

LASA utilizes a process known as the Modified Ludzack-Ettinger (MLE) Activated Sludge Process. The MLE process is used to achieve Biological Nutrient Removal (BNR). The MLE process AO-System-from-Roofachieves BNR through nitrification/denitrification. The system has two sets of parallel tanks or trains. Each train consists of 6 sections in series. A mixture of primary effluent and return activated sludge, commonly known as the biomass, flows first into 3 smaller anaerobic selector zones that are mechanically mixed. This is where denitrification occurs. Flow then passes into the aerated zones where diffused air mixes the biomass and provides it with the required oxygen. This is where nitrification occurs. The biomass also converts suspended, dissolved and colloidal material into settleable material, where it can be removed by settling in the next stage of the process.

Final Clarifiers

There are 3 final clarifiers. Two 100′ diameter tanks and one 142′ diameter tank. These clarifiers remove the converted material by it settling to the bottom of the tank and the remaining floatable scum to the surface. Through an underflow pumping system, the settled material is used to re-seed the activated sludge process on a continuous basis. Clean water overflows the weirs of these tanks.

There are 3 final clarifiers. Two 100′ diameter tanks and one 142′ diameter tank. These clarifiers remove the converted material by it settling to the bottom of the tank and the remaining floatable scum to the surface. Through an underflow pumping system, the settled material is used to re-seed the activated sludge process on a continuous basis. Clean water overflows the weirs of these tanks.

Disinfection

Disinfection is achieved by adding a sodium hypochlorite solution to the final clarifier overflow. Sodium Hypochlorite is a weak chlorine solution. The chlorine contact tanks provide the proper detention time for the chlorine to react with any pathogens or viruses in the wastewater. After disinfection, any residual chlorine is removed by adding a sodium bisulfite solution prior to its release to the Susquehanna River.

Disinfection is achieved by adding a sodium hypochlorite solution to the final clarifier overflow. Sodium Hypochlorite is a weak chlorine solution. The chlorine contact tanks provide the proper detention time for the chlorine to react with any pathogens or viruses in the wastewater. After disinfection, any residual chlorine is removed by adding a sodium bisulfite solution prior to its release to the Susquehanna River.

Solids Handling

Material removed from the wastewater processes are commonly referred to as biosolids. Biosolids are stabilized using anaerobic digestion and dewatered by a centrifuge. A centrifuge is piece of equipment that mechanically removes excess water from the biosolids. The solid content of the biosolids is typically increased from 1.5% to 23% after being processed with a centrifuge. The biosolids are then dried in a thermal dryer to produce a >95% solid material.

Material removed from the wastewater processes are commonly referred to as biosolids. Biosolids are stabilized using anaerobic digestion and dewatered by a centrifuge. A centrifuge is piece of equipment that mechanically removes excess water from the biosolids. The solid content of the biosolids is typically increased from 1.5% to 23% after being processed with a centrifuge. The biosolids are then dried in a thermal dryer to produce a >95% solid material.

Biosolids Storage

Biosolids are stored on a covered macadam pad awaiting transport for final reuse/disposal. Biosolids are utilized for fertilizer on farms or disposed of at a local landfill.

Biosolids are stored on a covered macadam pad awaiting transport for final reuse/disposal. Biosolids are utilized for fertilizer on farms or disposed of at a local landfill.